Design and application of protective door lock for drop testing machine

In the process of modern industrial production, safety protection measures are particularly important. As an important testing equipment, the drop tester should ensure the product quality and the safety of operators. Therefore, the protection design of the drop tester is very important, and the door lock of the protection door is the key link.

I. Introduction of Drop Testing Machine

The drop tester is a testing device used to simulate the possible drop of products in actual use. By evaluating the drop performance of the product, it is determined whether the structural reliability and impact resistance meet the requirements of relevant standards. Widely used in electronic products, packaging materials and other fields.

Second, the importance of the protective door of the drop testing machine

Because the drop test may produce great vibration and noise, and debris splashing may also occur, if there is no proper protective facilities, it will bring great safety hazards to the staff.

1. Prevent objects from being ejected from the inside to cause injuries: this risk is avoided by installing solid and reliable protective doors and corresponding locking mechanisms;

2. Reduce noise pollution:  Reasonable selection of materials and sound insulation treatment can effectively reduce the noise decibel value in the working environment;

Reasonable selection of materials and sound insulation treatment can effectively reduce the noise decibel value in the working environment;

3. Improve the overall aesthetics: a reasonable appearance can not only increase the aesthetics of the machine itself, but also improve the user's goodwill towards the brand or model;

Third, the role and classification of the protective door lock of the drop testing machine

1. Role:

(a) Ensure that the air circulation in the laboratory is good and the test results will not be affected by accidental opening;

(b) It can be quickly unlocked in case of emergency so as to escape in time;

(c) enhance that stability and durability of the whole system;

2. Classification:

According to the different opening modes, it can be divided into manual and automatic types:

(a) Manual mode usually needs to manually complete the closing process and fix the position by means of keys or password locks;

(b) The advantage of automatic mode is that it can realize quick switching action without extra manpower input, and it can automatically lock after the sensor senses abnormal signals to prevent accidents.

Iv. technical requirements for the door lock of the drop tester.

In order to ensure safety and reliability, the protective door lock of the drop tester must meet the following technical requirements:

1. The structure is stable and reliable-the main frame is made of high-strength steel, and the corrosion resistance is enhanced by special surface treatment; It is assembled with high-quality metal fittings, so that it can maintain a good connection state even in harsh environment;

2. The switch is smooth and free from jamming-installing a pulley track at the bottom of the door body can effectively reduce the friction resistance, so that the user can easily control the opening and closing process;

3. It has the function of emergency unlocking-when there is an emergency, such as fire and explosion, it should have a one-button quick release mechanism to get the trapped people out of the dangerous area as soon as possible;

V. Summary

To sum up, for the drop testing machine, the door lock of the protective door is one of the important components to ensure the safety of the operators. Only by reasonable design and correct selection of the appropriate model can the expected effect be truly achieved. In the future, with the continuous improvement of science and technology, I believe that more advanced technologies and innovative design concepts will be introduced into this field. Let us wait and see!

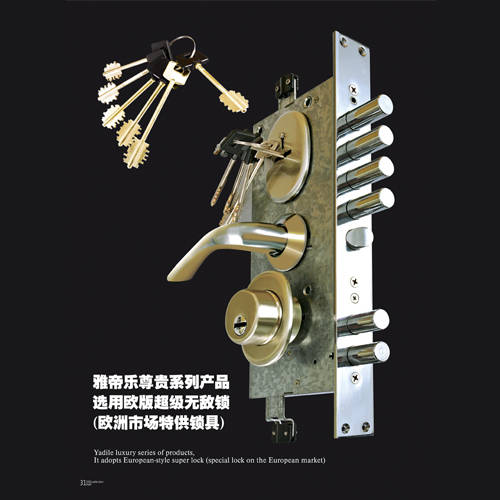

Rec. Prods.

Tags:

Addresses:https://tepinji.com/gsxw/2407.html