Design and Application of Side Hinge of Anti-leakage Protection Box

In today's society, electrical equipment has become an indispensable part of our life and work. However, in the process of using these electrical equipment, the safety problem has also become one of the important topics we must face. Among them, the anti-leakage protection box is one of the key devices to ensure the safety of electricity use, and its internal structure design is directly related to the safety and durability of the equipment, especially its side panel hinge part.

First, the role of the hinge of the side plate of the anti-leakage protection box

1. Safety guarantee: As the main component connecting the side plate and the box body of the anti-leakage protection box, the hinge not only needs to bear the weight of the side plate, but also ensures that the side plate can be opened and closed freely, firmly and stably, so as to prevent the side plate from falling off due to the damage of the hinge and causing safety accidents.

2. Convenient maintenance: A good hinge structure can make it easier for workers to open or close the side plate for maintenance operation, and reduce the risk of wear caused by frequent opening.

3. Sealing performance: High-quality hinges are helpful to improve the sealing effect of the whole anti-leakage protection box and prevent impurities such as dust from entering the equipment to affect the working state of the circuit.

Second, the design requirements of the side panel hinge of the leakage protection box

1. Material selection: usually made of stainless steel to ensure that the hinge has sufficient strength and corrosion resistance; At the same time, we also need to consider the cost factor and choose materials with high cost performance.

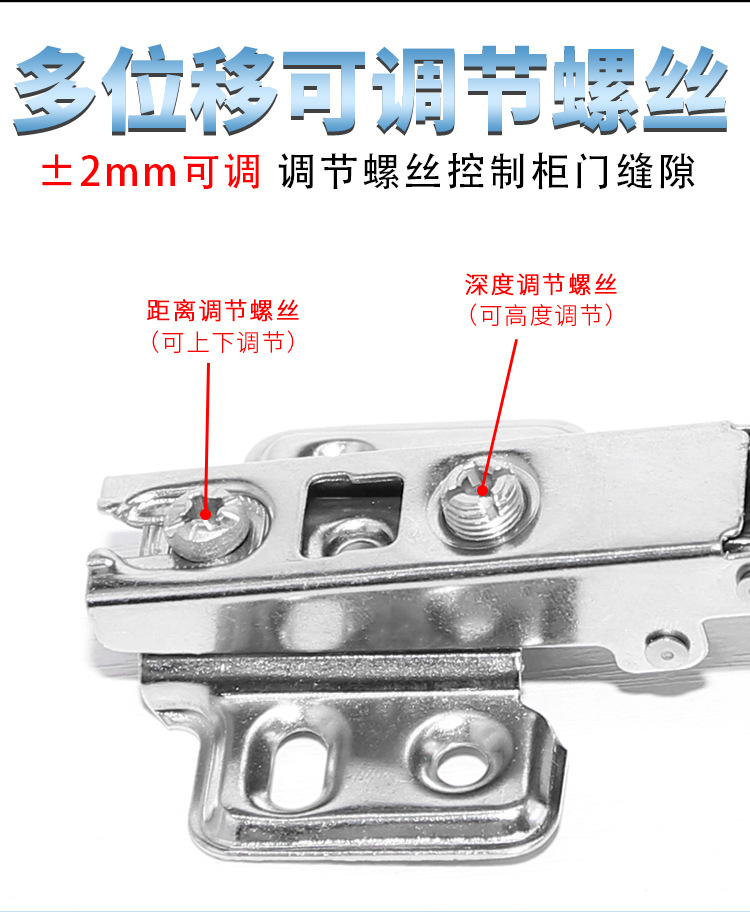

2. Structural optimization: according to the actual application scenario, determine the appropriate size specifications (such as width and thickness) and make finite element analysis and calculation of the product in combination with mechanical principles to ensure the overall structure is reasonable and reliable;

3. Process treatment: For some key parts, such as the pin hole position, the precision and surface smoothness of the parts can be improved by finishing, so as to achieve the effect of reducing friction.

Third, the case analysis-a case of improving the hinge of the side plate of a brand anti-leakage protection box

The original hinge of this leakage protection box has the following problems:

(1) the opening angle is limited;

(2) The locking mechanism is easy to loosen;

(3) The disassembly is complicated.

In view of the above defects, technicians have taken the following improvement measures:

1. Change the original one-sided fixed locking mode into the double-sided buckle locking mode. And the locking stability is improved;

And the locking stability is improved;

2. Increase the limit block to expand the maximum rotation range to more than 180, which is convenient for daily maintenance;

3. The disassembly steps are simplified, and quick replacement can be realized only by pressing lightly.

Through this transformation and upgrading, the products not only meet the customer's requirements for aesthetics, but also enhance the practical functionality and reliability, which has been recognized and praised by the majority of users.

To sum up, although the hinge of the side plate of the leakage protection box is only a small detail, its importance is self-evident. In the future, with the development of science and technology and the change of market demand, more new high-performance hinges will be developed to bring more possibilities to the industry.

Rec. Prods.

Tags:

Addresses:https://tepinji.com/Machi/4017.html