Importance and selection of door lock for protective door of casting cleaning equipment

With the continuous development and progress of industrial production, all kinds of mechanical equipment are more and more widely used in production. Among many mechanical equipment, casting cleaning equipment, as one of the key links in the casting process, not only ensures the quality of castings, but also plays an important role in ensuring the safety of workers. Among them, the protective door lock of casting cleaning equipment is a vital line of defense.

A, the role of protective door lock

1. Protect the personal safety of operators.

When using casting cleaning equipment, in order to prevent the occurrence of safety accidents caused by mechanical failure or human misoperation, it is necessary to install protective door locks with automatic locking function. When the protective door is opened, the casting cleaning equipment will Stop working immediately and restart only when the protective door is completely closed and locked, thus effectively avoiding the occurrence of accidental injuries.

Stop working immediately and restart only when the protective door is completely closed and locked, thus effectively avoiding the occurrence of accidental injuries.

2. Prevent unauthorized personnel from entering dangerous areas.

Because the casting cleaning equipment is usually running at high speed and accompanied by loud noise, it is necessary to strictly restrict non-professionals from entering the job site. By installing protective door locks with high-level security devices such as electronic locks or password locks, unauthorized personnel can be effectively prevented from entering and leaving at will, thus ensuring the smooth and orderly operation of the whole production line.

Second, the selection criteria of protective door locks

1. Material requirements

The door lock of the protective door should be made of materials with high strength and good corrosion resistance, such as stainless steel and alloy steel. At the same time, it is necessary to consider whether the surface treatment process is fine enough to achieve the purpose of rust prevention and corrosion prevention.

2. Structural design

The structure of the protective door lock should be compact and reasonable, and it is not easy to be deformed and damaged; And should have enough bearing capacity, can withstand a certain external impact and will not easily break off.

3. Safety performance

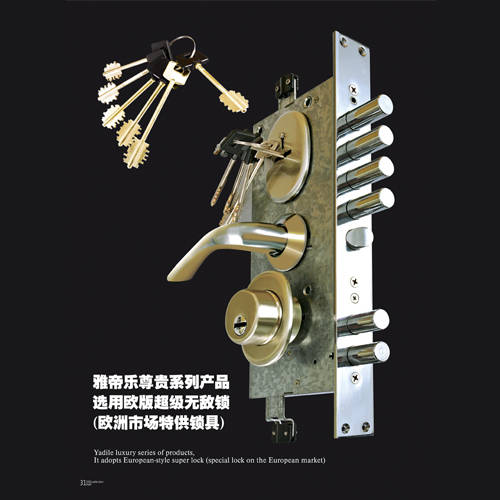

First of all, it should be equipped with a double safety mechanism (that is, primary lock+secondary lock), which can maintain an effective closed state even if one of them fails;

Secondly, it is better to have a power-off self-locking function to ensure that the door body cannot be illegally opened in case of sudden power failure.

Third, the conclusion

To sum up, in order to improve the overall safety level and work efficiency of casting cleaning equipment, it is suggested that enterprises must pay attention to purchasing products that meet the above conditions when purchasing related products, and conduct regular inspection and maintenance to replace old and damaged parts in time, so as to maximize the due value of these accessories!

Rec. Prods.

Tags:

Addresses:https://tepinji.com/Machi/4015.html