Topic: Importance and selection of distribution box lock for product reliability testing equipment

I. Preface

In modern industrial production, the quality and performance of products are one of the key factors that determine the competitiveness of enterprises. In order to ensure the stability of product quality and performance, it is necessary to carry out strict product reliability tests on various mechanical equipment. Among them, in the process of product reliability testing, distribution box lock plays a vital role as an important part of ensuring electrical safety. This paper will focus on the importance of "distribution box lock of product reliability test equipment" and how to choose the right distribution box lock correctly.

Second, the importance of distribution box lock

1. Ensure the personal safety of operators.

Product reliability testing usually involves the detection of equipment working state in high voltage power supply environment, so effective measures must be taken to prevent accidents when these tests are carried out. At this time, a qualified and reliable distribution box lock can effectively prevent irrelevant personnel from opening or closing the circuit switch without authorization, and can prevent unauthorized operation, thus reducing the accident risk and protecting the life and property safety of workers.

2. Ensure the stable operation of equipment.

For some reasons (such as accidental touch, malicious destruction, etc.), if the distribution box is opened at will by non-professionals, it may affect the power supply of the whole production line, which may lead to failure or even more serious consequences. Therefore, in practical application, using high-performance and high-precision distribution box lock device can not only improve the overall security of the system, but also enhance the economic benefits and social image of enterprises to a certain extent.

Third, how to correctly choose the distribution box lock?

1. Clear usage scenario requirements

Different industries have different specific requirements for distribution box locks. For example, special attention should be paid to explosion-proof and corrosion-proof performance in chemical plants; In the hospital, it is necessary to consider the characteristics of easy cleaning and disinfection. Therefore, when selecting, we should first determine the corresponding demand points according to the characteristics of our own industry.

2. Pay attention to material quality and manufacturing process level.

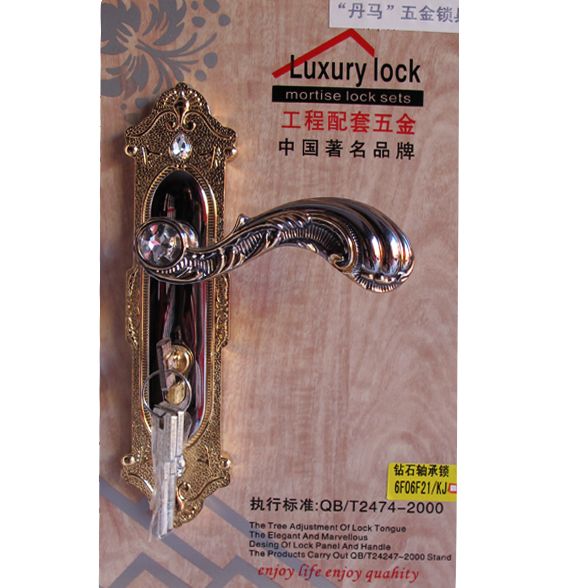

The keyhole made of high-quality metal has high tensile strength and wear resistance, which can prolong the service life; In addition, we should also pay attention to check whether the surface treatment effect is good (such as scratches and oxidation spots), which is related to future maintenance.

3. Consider the degree of intelligence

With the progress and development of science and technology, "smart factory" has become one of the future development directions. To this end, many new models of power distribution cabinet locks are integrated with electronic induction function-users can easily open and close by pressing a button without carrying heavy and complicated traditional mechanical keychains. In addition, intelligent products can also be connected to the central control system through wireless network, which can monitor the state change of each node in real time and send out alarm information in time to remind relevant personnel to handle it.

Fourth, summary

To sum up, No matter from which point of view, it is a very necessary step to reasonably equip high-quality distribution box locks. It can not only help us avoid potential security risks, but also bring great convenience and efficiency improvement space for daily management. I hope the above contents can provide some reference value for everyone!

No matter from which point of view, it is a very necessary step to reasonably equip high-quality distribution box locks. It can not only help us avoid potential security risks, but also bring great convenience and efficiency improvement space for daily management. I hope the above contents can provide some reference value for everyone!

Rec. Prods.

Tags:

Addresses:https://tepinji.com/Machi/2252.html