Important role of aluminum alloy hinge in cold storage equipment

With the rapid development of modern cold chain logistics, the demand for cold storage is increasing. As one of the important parts of cold storage, the cold storage door bears the task of frequent opening and closing in daily use. In these processes, the key performance such as opening and closing flexibility and durability of the refrigerator door often depends on a small component-hinge.

First, the characteristics of aluminum alloy materials

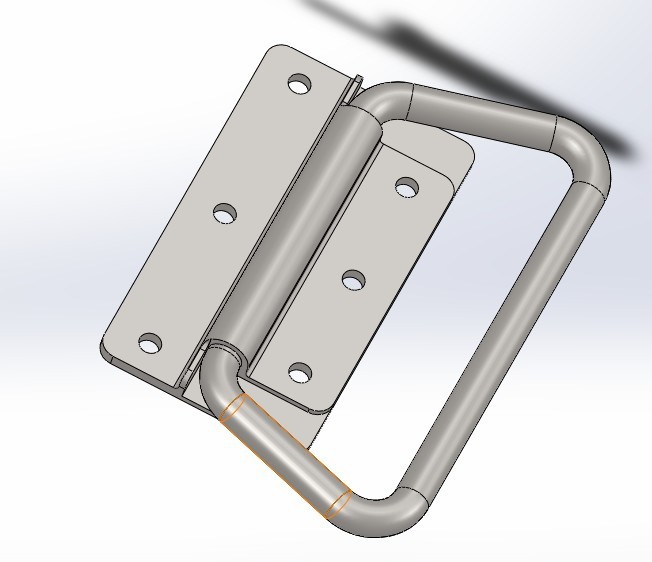

Hinge ann A mechanical device installed between two objects to allow relative rotational movement, which is mainly used for the connection and activity of doors and windows and other structures. The aluminum alloy hinge in cold storage equipment is made of aluminum alloy. Aluminum alloy is a kind of light metal alloy, which has good mechanical properties, machinability and corrosion resistance, and is light in weight and easy to process, and is widely used in various fields.

A mechanical device installed between two objects to allow relative rotational movement, which is mainly used for the connection and activity of doors and windows and other structures. The aluminum alloy hinge in cold storage equipment is made of aluminum alloy. Aluminum alloy is a kind of light metal alloy, which has good mechanical properties, machinability and corrosion resistance, and is light in weight and easy to process, and is widely used in various fields.

Second, the application of aluminum alloy hinge in cold storage

1. Low temperature resistance: The internal temperature of cold storage is usually kept at minus ten degrees or even lower, while hinges made of ordinary steel will be deformed or broken due to cold shrinkage; In contrast, aluminum alloy materials can remain stable in extremely cold environment without embrittlement.

2. Rust prevention and corrosion protection: A dense protective film will be formed on the surface of aluminum alloy after anodic oxidation treatment, which can effectively prevent moisture and salt erosion, so it will not rust and corrode even if it is exposed to humid environment for a long time.

3. High strength and good toughness: Compared with other metal products, aluminum alloy hinges not only have higher strength and hardness, but also have better plasticity and impact resistance, and can withstand greater pressure without being easily damaged.

4. Excellent sealing performance: considering the thermal insulation effect in the design, high-quality sealing strips are used with tight bite structure to realize all-round sealing, so as to avoid the increase of energy consumption caused by the invasion of external hot air.

Third, the maintenance matters needing attention

In order to ensure the long-term stable operation and prolong the service life of aluminum alloy hinges, users should also pay attention to the following points:

1. Regularly check whether the fasteners are loose;

2. Clean and lubricate the rotating parts to reduce wear;

3. If any abnormality is found, timely repair and replace new parts so as not to affect the normal functioning of the whole function;

4. Avoid problems such as deformation and damage caused by heavy objects hitting or forcibly pulling away.

To sum up, as an efficient and reliable connection mechanism, aluminum alloy hinge has become one of the indispensable standard configurations in the refrigeration industry today. Reasonable selection of specifications and models combined with scientific and reasonable maintenance and management measures can significantly improve the comprehensive efficiency of equipment and reduce operating costs.

Rec. Prods.

Tags:

Addresses:https://tepinji.com/Machi/1769.html